As the core power source for modern electronic devices and electric vehicles, lithium-ion batteries are widely used in smartphones, electric vehicles (EVs), and personal light electric vehicles (PLEVs) such as e-scooters and e-bikes. Despite their advantages of high energy density, long cycle life, and fast charging, thermal runaway (TR) remains the most severe safety hazard of lithium-ion batteries. When the battery temperature exceeds a critical threshold (usually 150-180℃), it triggers an uncontrollable self-heating cycle, releasing a large amount of heat and toxic gases, leading to fires or even explosions.

As the core power source for modern electronic devices and electric vehicles, lithium-ion batteries are widely used in smartphones, electric vehicles (EVs), and personal light electric vehicles (PLEVs) such as e-scooters and e-bikes. Despite their advantages of high energy density, long cycle life, and fast charging, thermal runaway (TR) remains the most severe safety hazard of lithium-ion batteries. When the battery temperature exceeds a critical threshold (usually 150-180℃), it triggers an uncontrollable self-heating cycle, releasing a large amount of heat and toxic gases, leading to fires or even explosions.

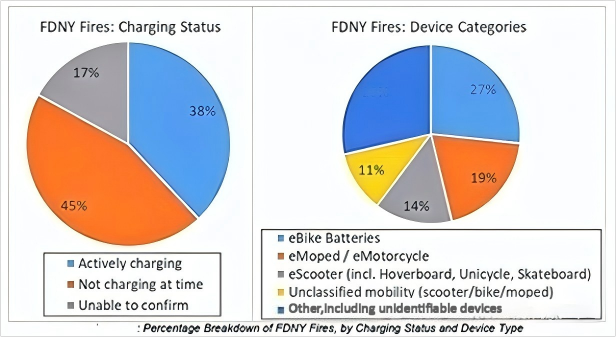

With the frequent occurrence of PLEV battery fire accidents, it has become particularly urgent to deeply understand the thermal runaway mechanism and take preventive measures. This article will conduct a systematic analysis from the mechanism to the solutions.

I. Essential Characteristics of Thermal Runaway

Thermal runaway is a chain chemical reaction that occurs when the heat generation rate inside a lithium-ion battery exceeds its heat dissipation capacity, with the characteristic of self-sustaining acceleration until all combustibles in the battery are consumed. Its core manifestations include:

1. Uncontrollable Temperature Rise

- Trigger threshold: Exothermic reactions occur between electrolyte and electrode materials at 150-180℃.

- Temperature rise rate: The heat released by the reaction can cause the temperature to soar above 1000℃.

- Propagation risk: High temperatures may cause thermal propagation in adjacent battery cells.

2. Gas Eruption and Shell Rupture

- Gas composition: Electrolyte decomposition produces flammable and toxic gases such as hydrogen and carbon monoxide.

- Pressure accumulation: A sudden increase in internal pressure of the sealed shell leads to rupture.

- Secondary disasters: Erupted gases may explode when encountering sparks.

3. Fire and Toxic Gas Release

- Combustion characteristics: Flame temperature exceeds 1000℃, and cathode materials decompose to release oxygen that supports combustion.

- The traditional suffocation fire extinguishing method is ineffective, requiring continuous cooling control.

- Toxic emissions: Release of corrosive gases such as hydrofluoric acid (HF), which harms the respiratory tract.

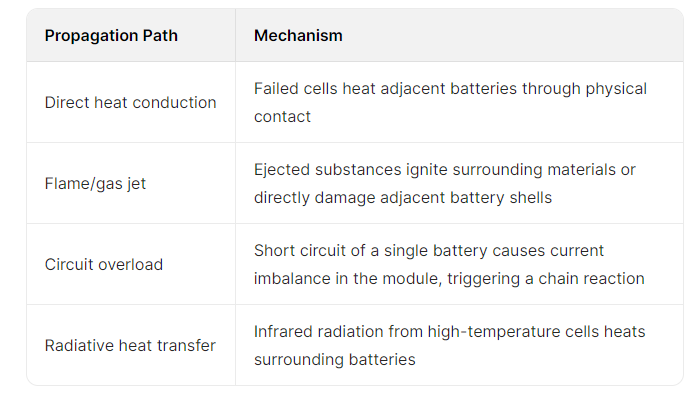

4. Thermal Propagation Mechanism

II. Analysis of Four Inducing Factors for Thermal Runaway

1. Mechanical Abuse

- Collision and puncture: External forces cause separator damage, leading to internal short circuits (e.g., e-vehicle fall accidents).

- Vibration fatigue: Continuous vibration causes micro-cracks in electrodes, increasing the risk of local overheating.

- Engineering protection suggestions: In the structural design of battery modules, using high-strength SMT copper strip connections can improve mechanical stability and reduce vibration-induced micro-damage.

2. Electrical Abuse

- Overcharging or Overdischarging causes deterioration of the internal structure

- Overcharging (>4.2V/cell): Lithium plating on the anode forms dendrites that penetrate the separator.

- Over-discharging (<2.5V/cell): Dissolution of copper current collectors leads to internal short circuits.

- BMS failure: The battery management system malfunctions and cannot prevent abnormal states.

3. Thermal Abuse

- High ambient temperature: Batteries are exposed to environments above 60℃ (e.g., inside vehicles under intense sunlight).

- Insufficient heat dissipation: Batteries in modules are stacked too densely, causing heat accumulation.

- Thermal management defects: Lack of effective heat dissipation path design.

4. Manufacturing Defects

- Metal impurities: Micron-sized metal particles remaining in the production process penetrate the separator.

- Separator defects: Uneven coating leads to local insulation failure.

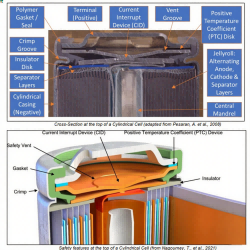

- Inferior cells: Counterfeit batteries lack safety valves (CID) and positive temperature coefficient (PTC) protection.

Ⅲ.Thermal Runaway Prevention Technology System

1. Improvements in Thermal Management Design

- Thermal insulation barriers: Ceramic coatings/aerogel materials are used to delay thermal propagation.

- Cooling systems: EVs: Liquid cooling circulation pipelines; PLEVs: Enhanced heat sinks + air cooling design.

- Structural optimisation: At the module level, a reasonable layout of high thermal conductivity SMT copper strips can establish efficient lateral heat dissipation paths, and combined with phase change materials to improve thermal balance.

2. Intelligent Battery Management System (BMS)

- Triple monitoring: Real-time detection of voltage, current, and temperature.

- Active protection: Automatic cut-off for overcharging/over-discharging; Dynamic balancing of cell voltages.

- Early warning mechanism: Wireless transmission of abnormal alarm signals.

3. Intrinsically Safe Materials

Comparison of different battery materials

4. User-side Protection Measures

- Charging specifications: Use original chargers; Avoid overnight charging; Maintain a charge level between 20%-80%.

- Storage requirements: Cool and ventilated environment, away from flammable substances.

- Abnormality identification: Immediately stop using it when a bulge or peculiar smell is found.

Ⅳ. Cutting-edge Monitoring Technologies

- Regulatory standards: Enforce safety certifications such as UL 2271 and IEC 62619.

- Manufacturer responsibilities: Establish a cell traceability system; Eliminate the circulation of inferior batteries.

- Technological innovation: Promote laser welding terminal technology to ensure the reliability of electrical connections and reduce local overheating caused by contact resistance.

Ⅴ.Conclusion

With the rapid development of electric transportation and energy storage industries, the prevention of lithium-ion battery thermal runaway requires multi-dimensional collaboration in material research and development, engineering design, and user education. By optimising thermal management designs (such as SMT copper strip heat conduction schemes), popularising intelligent BMS systems, and promoting safe chemical systems like LFP, we can build a more reliable energy storage ecosystem.